In the world of panel furniture, if cutting determines the "skeleton" of the board, then Edge Banding determines its "soul" and "lifespan." For consumers, the most intuitive standard for judging the high-end quality of a custom wardrobe or cabinet is often not the interior of the board, but the perfection of the edge treatment.

Edge Banding quality directly affects the aesthetic appearance, moisture resistance, and formaldehyde sealing safety of furniture. With the increasing demands for quality in the global furniture market, rough hand-banding has gradually been phased out. Modern manufacturing companies are placing greater emphasis on automated Edge Banding, attempting to solve the problems of labor shortages and inconsistent quality through technological upgrades.

This is precisely why the demand for high-quality Automatic Edge Banding Machines has surged. As a high-end automated machine supplier specializing in panel processing, Caelus understands that an excellent Edge Banding machine is not just a production tool, but a key driver helping furniture factories transform from traditional manufacturing to intelligent machine factories.

What is an Edge Bander?

In simple terms, an Edge Bander is a specialized machine that applies and trims Edge Banding material onto the cross-section of a board.

It plays a crucial role in furniture production. Most boards (such as particleboard and MDF) have rough edges after cutting and are prone to moisture absorption and expansion. We need to use Edge Banding to physically seal them. This not only prevents moisture intrusion and reduces the release of harmful gases from within the board, but also provides impact protection and decoration.

While simple hand tools still exist on the market, professional woodworking Edge Banding machines are vastly different. Modern industrial-grade Edge Banding machines integrate mechanical, pneumatic, electronic technologies and software control systems, enabling micron-level processing precision at high speeds. For brands like Caelus, which emphasize heavy-duty structures and high stability, Edge Banding machines are more like precision instruments on the production line, ensuring that every board has a perfect edge.

Edge Banding Strips and Edge Banding Adhesive: Types, Pain Points, and Solutions

To understand Edge Banding machines, we must first understand their two partners: Edge Banding strips and adhesive.

1. What is Edge Banding?

Edge Banding is like a protective layer for furniture.

Common materials include:

PVC/ABS: This thermoplastic is the most commonly used material, offering excellent impact resistance and a rich variety of colors and textures.

Wood Veneer: It is used in high-end solid wood veneer furniture, emphasizing a natural texture.

Melamine: It has a high cost-performance ratio, often used for cabinet interiors.

Aluminum Edge Banding: It is a top choice for modern minimalist styles, suitable for high-wear scenarios like kitchen cabinets.

2. What is Edge Banding Adhesive?

Edge Banding adhesive is the medium that connects the board material to the Edge Banding.

EVA Hot Melt Adhesive: A traditional choice with highly versatile, but with generally average heat and water resistance.

PUR Reactive Hot Melt Adhesive: A modern high-end standard. It not only has extremely high bonding strength but is also waterproof and heat-resistant, with extremely fine adhesive lines—making it the key to achieving a "seamless Edge Banding" effect. However, PUR requires extremely precise temperature control of the glue pot.

3. Production Pain Points and Caelus' Technical Solutions

In actual production, factories often face problems such as glue separation, black lines, and uneven edge trimming. The following table analyzes these pain points and their corresponding solutions:

Table 1: Common Edge Banding Pain Points & Solutions

| Pain Point | Root Cause | Solution with High-End Edge Bander |

|---|---|---|

| Edge Peeling | Unstable temperature or uneven glue application. | Adopt a machine with Servo Control for precise glue dosing and temperature monitoring. |

| Visible Glue Line | Poor pressure application or wrong glue type. | Adopt to PUR glue capability and heavy-duty pressure rollers. |

| Rough Trimming | Tool vibration or blade wear. | Heavy-duty structure reduces vibration; Auto-compensation for tool wear. |

| Corner Defects | Manual adjustment errors. | Automatic Edge Banding machine with corner rounding units eliminates manual work. |

4. Caelus' Advantages in Edge Banding and Adhesive Treatment

Caelus' machine was designed to solve the aforementioned pain points. Our servo system precisely controls the amount of adhesive, avoiding overflow or insufficient adhesive; the heavy-duty machine structure ensures flawless physical contact between the Edge Banding and the board during high-speed pressing. Whether it's PVC or the more challenging PUR Edge Banding, Caelus handles it with ease, delivering a smooth and delicate Edge Banding effect.

Working Principle of Edge Banding

The workflow of a modern Automatic Edge Banding Machine is like a precise relay race, with the main processes including:

Pre-milling: It using diamond tools to trim the edges of the board, eliminating saw marks, and ensuring an absolutely flat bonding surface.

Gluing: The glue pot evenly applies molten adhesive to the board or Edge Banding tape.

Snapping & Pressing: The tape feeding mechanism feeds the Edge Band, and the pressure rollers press it firmly against the board.

Trimming: Removes excess Edge Banding material from the top and bottom edges. The trimming blade shapes the edges into perfect rounded corners or chamfers.

Corner Rounding: Treats the four corners of the board Edge Banding, making them smooth and rounded, preventing sharp edges.

Scraping: Removes blade marks and excess adhesive residue.

Buffing: A high-speed rotating soft cloth wheel cleans and polishes the edges, making the color brighter.

Caelus has introduced an intelligent control system that monitors the status of each unit in real time. If any deviation occurs in any step, the system will automatically issue a warning or make fine adjustments to ensure the stability of each process.

Edge Banding Machine Types: From Entry-Level to Intelligent Automation

Intelligent Automation Edge Banding Machine

The market offers a wide variety of Edge Banders, mainly divided into:

Manual/Semi-Automatic Edge Banding Machines: They are suitable for irregularly shaped boards or very small workshops, relying on manual experience and having low efficiency.

Automatic Edge Banding Machine: It automatically completes all processes, making it suitable for standardized production.

Double-Ended Edge Banding Line: It completes edge banding on both sides in a single pass, suitable for large-scale flooring or door panel production.

CNC Integrated Edge Banding Center: It combines CNC functionality, making it suitable for complex customized processing.

For most medium to large-sized furniture factories, Caelus recommends choosing high-performance fully automatic models. Our machine is positioned for "mid-to-high-end manufacturing," ensuring high speed while boasting electronic system reliability far exceeding ordinary models, making it the best choice for capacity upgrades.

Application Scenarios of Edge Banding Machines in Furniture Manufacturing

Edge Banders are active in various sub-sectors:

Whole-House Customization (Cabinets/Wardrobes): This is the sector with the highest requirements for Edge Banding, especially for door panels, which must meet both moisture resistance and aesthetic standards.

Office Furniture: Typically uses thicker Edge Bands (such as 2mm PVC), requiring machine with powerful edge trimming capabilities.

It often involves thick board Edge Banding and the application of special materials. In these scenarios, Caelus's automated machine, with its outstanding practical performance, has helped customers solve the challenge of consistent quality in mass production.

Why Must Modern Factories Use Automatic Edge Banding Machines?

Automatic Edge Banding Machines

In the era of Industry 4.0, relying on manual labor or low-end machine is no longer viable. The reasons for upgrading to automated Edge Banding machines are obvious:

Higher Precision: Human hands can tremble, but servo motors do not. Caelus's servo precision control technology ensures processing errors are controlled at the micrometer level.

Increased Production Efficiency: Our "high-speed processing" advantage enables a significant exponential increase in output per unit time.

Reduced Dependence on Craftsmen: Standardized machine operation reduces the demand for highly paid skilled workers.

Consistent Quality: Every panel produced is of consistent quality, whether it's a morning or evening shift.

Suitable for Full Panel Processing Integration: Only fully automated machine can seamlessly integrate with automatic loading/unloading machines and CNC systems.

Intelligent Maintenance: Caelus edge banding machines are equipped with a built-in intelligent diagnostic system that can predict maintenance needs in advance, thus avoiding unexpected downtime.

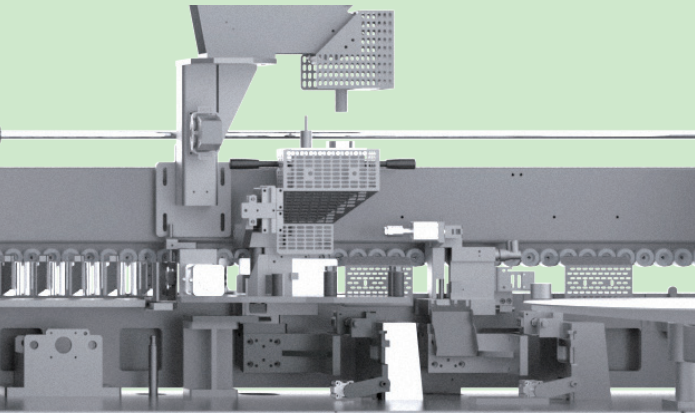

Analysis of Core Modules of Edge Banding Machines

The core of a good woodworking Edge Banding machine lies in the details:

Pre-milling Unit: Determines the baseline for Edge Banding. Caelus uses a high-power motor to prevent edge chipping.

Glue Pot System: Supporting quick switching between EVA and PUR adhesives is standard in modern models.

Pressure System: The sensitivity of pneumatic pressure control directly affects the edge banding adhesion strength.

Control System: A powerful PLC + servo system is the brain. Caelus's electrical control system has undergone rigorous testing and operates stably even in high-temperature and dusty environments.

How to Choose the Right Edge Banding Machine?

Faced with numerous Edge Banding manufacturers, how should a factory choose?

Consider Capacity: Calculate your average daily processing length and select a feed speed that matches your needs(e.g., 20m/min or higher).

Consider Material: Confirm whether you need to process high-gloss boards or use PUR adhesive.

Consider Automation Level: Determine whether you need automatic lifting and automatic belt changing functions.

Consider Brand and After-Sales Service: Choosing a professional automation machine supplier like Caelus means you're not just buying a machine, but also long-term technical support.

Common Problems and Solutions in Edge Banding

On the production floor, the most troublesome problems are:

Poor adhesion: Check glue temperature and quantity.

White edges/black lines: Adjust the edge trimming knife position or clean the glue pan.

Scratches on the board surface: Check the pressure rollers and worktable for foreign objects.

Caelus' intelligent Edge Banding machine has automatic detection functions; many abnormal physical parameters can be displayed intuitively on the screen, greatly reducing troubleshooting time.

Automated Production Line: Edge Banding vs. Traditional Methods

To more intuitively demonstrate the value of automation, we have created the following comparison table:

Table 2: Automatic vs. Traditional Edge Banding

| Feature | Traditional / Manual Method | Automatic Edge Banding Machine (Caelus) |

|---|---|---|

| Speed | Slow (< 5m/min) and intermittent | High speed (> 20m/min) and continuous |

| Precision | Low, depends on operator skill. | Micro-precision via Servo Control. |

| Glue Line | Often thick and visible. | Thin, consistent, supports Zero-Glue-Line (PUR). |

| Labor Cost | High (requires skilled craftsmen). | Low (one operator can manage the production line). |

| Integration | Standalone, manual handling. | Fully integrated into Panel Processing lines. |

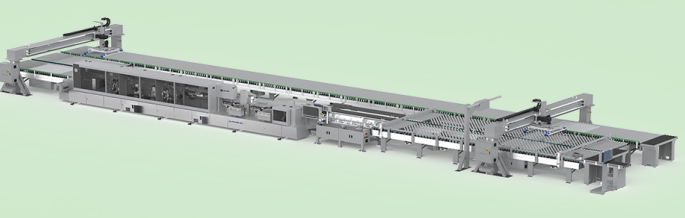

The Position of the Edge Banding Machine in Panel Processing Line Automation

Panel Processing Line Automation

The Edge Banding machine is not an isolated entity. In Caelus's intelligent furniture factory solution, it occupies a crucial, bridging position:

It connects to the front-end panel saw (electronic saw) or CNC cutting center to receive precisely cut panels. Via a conveyor belt, the panels automatically enter the Edge Banding machine.

At the back end, it connects to an automatic rotary line or drilling center.

The entire process is integrated through the MES system, achieving "groundless" production. This is precisely Caelus's strength in Edge Banding machines, boasting extremely high system integration capabilities.

Industry Trends of Leading Edge Banding Manufacturers

Future Edge Banding technology is developing in several directions:

Zero-glue line technology: Laser Edge Banding and hot air Edge Banding are becoming increasingly common, pursuing ultimate aesthetics.

High-speed and heavy-duty: Pursuing faster production cycles and more stable machine bodies.

AI parameter optimization: The machine can automatically adjust parameters based on panel thickness and ambient temperature.

As a professional and experienced Edge Banding machine manufacturer, Caelus has already embraced these trends. Our new generation of models leads the furniture manufacturing machinery industry in heavy-duty construction and intelligent maintenance systems.

FAQ

Q1: What is an Edge Bander?

A: It is an industrial device used to automatically attach and trim Edge Bands to the edges of furniture panels, protecting and enhancing the appearance of furniture.

Q2: What is the difference between Edge Banding and Edge Band?

A: Edge Band refers to the Edge Banding material itself (such as PVC strips); Edge Banding (the process) refers to the entire operation of attaching and trimming Edge Bands.

Q3: What is the difference between PUR and EVA glue?

A: EVA is inexpensive and easy to use but has poor water resistance; PUR has strong adhesion, fine glue lines, and is waterproof and heat-resistant, making it the preferred choice for high-quality furniture, but it requires a dedicated glue pot system.

Q4: How to choose the right Edge Banding machine for your needs?

A: The choice depends on your production volume, board type, and budget. If you prioritize high efficiency and long-term stability, we recommend Caelus' Automatic Edge Banding Machine.

Q5: Which factories are suitable for automated Edge Banding machines?

A: They are suitable for medium to large-sized custom furniture factories, cabinet factories, office furniture factories, and any enterprise that wants to reduce labor costs and improve product quality.

Conclusion: Edge Banding Quality is Key to Furniture Manufacturing

The perfect combination of Edge Banding strips, Edge Banding adhesive, and machine is the fundamental factor determining the quality of furniture. In a highly competitive market, upgrading to automation is an irreversible trend.

Owning a Caelus edge banding machine means you have the stability of a heavy-duty structure, the precision of a servo system, the amazing processing speed, and the wide process adaptability. As your trusted automation machine supplier, Caelus is ready to help you build a more competitive, modern production line.

Want to learn more about Caelus automated Edge Banding solutions? Welcome to visit our website and contact our technical experts for the most professional and tailored panel processing solutions to your needs.