In the highly competitive field of furniture manufacturing, the cutting process is the first hurdle that determines production capacity and quality. This article provides an in-depth analysis of why traditional factories must upgrade to CNC Panel Saws, explores their crucial role in panel processing, and reveals how the Caelus Aurora and Pilot series are reshaping production efficiency through automation technology.

Why Must the Furniture Manufacturing Industry Upgrade Cutting Machines?

In the context of modern industry, furniture manufacturing is undergoing a profound transformation from labor-intensive to technology-intensive. The production model that once relied on the experience of skilled craftsmen and manual saws is gradually becoming a bottleneck restricting enterprise development.

Traditional cutting methods face irreconcilable contradictions. On the one hand, consumer demand for customized furniture is increasingly fragmented, with orders containing a large number of non-standard-sized panels; on the other hand, market demands for shorter delivery cycles are increasing. In traditional panel processing workflows, frequent manual calculation of layouts and manual adjustment of guides are not only time-consuming but also highly prone to errors. Once dimensional deviations occur in the cutting process, subsequent edge banding, drilling, and even assembly will be negatively affected by a chain reaction.

In addition, rising raw material costs require factories to maximize the utilization of every square inch of board. Traditional machines lack intelligent optimization algorithms, resulting in high waste rates. Therefore, introducing high-precision, high-efficiency cutting solutions is no longer an option, but a necessity for survival.

What is CNC Panel Saw?

CNC Panel Saw is the perfect combination of computer numerical control technology and precision mechanical manufacturing. Unlike traditional sliding table saws that require manual pushing and pulling of panels, CNC Panel Saws automatically control the movement of the saw carriage, the lifting and lowering of the saw blade, and the gripping and positioning of the robotic arm through pre-programmed instructions.

Its core function lies in the CNC control system. This is like the machine's brain, precisely controlling servo motors and linear drive systems to control the panel positioning accuracy to the millimeter or even micrometer level. During the operation of the Panel Saw, the operator only needs to place the panel in the feeding area, input data or scan barcodes on the control panel, and the machine will automatically complete a series of actions such as beam clamping, main saw cutting, scoring saw anti-chipping treatment, and automatic unloading.

The core difference between this machine and traditional Panel Saws lies in its digital connectivity capabilities. It is no longer an isolated island, but rather the execution terminal for data across the entire digital factory.

Main Applications of CNC Panel Saws in Furniture Manufacturing

In actual production, Panel Saws cover the entire process of panel furniture manufacturing. Whether producing integrated cabinets, custom wardrobes, or office desks and chairs, the precise cutting of panels is the first step.

CNC Panel Saws demonstrate strong material adaptability. For base materials such as particleboard, MDF (medium-density fiberboard), and plywood, they can provide perfect straight cuts. Especially when dealing with panels with melamine paper or high-gloss acrylic finishes, CNC Panel Saws equipped with a double-blade structure can effectively prevent chipping and ensure a smooth and even cut.

In addition, with the application of new materials, modern Panel Saw uses have even extended to the processing of honeycomb panels, compact laminate panels, and some plastic composite materials. For furniture manufacturing companies pursuing high quality, it is the cornerstone for ensuring that all components are uniform in size and meet dimensional accuracy standards.

Why Do Furniture Factories Need to Upgrade from Traditional Panel Saws to CNC Panel Saws?

Steel countertop of CNC Panel Saws

Improved Cutting Accuracy, Reduced Rework and Material Waste

In panel processing, precision is money. Traditional cutting is limited by human visual errors and hand tremors, making it difficult to guarantee consistency in mass production. CNC Panel Saws, on the other hand, use a high-rigidity machine body structure combined with precision sensors, such as the Caelus Pilot S5 series, whose servo-controlled saw carriage ensures cutting accuracy during long-term operation. Precise cutting means that subsequent processes do not require secondary trimming, directly reducing the scrap rate.

Significantly Increased Production Efficiency, Adapting to Mass and Customized Production

Time is the most expensive cost in industrial production. CNC Panel Saws have the ability to cut multiple panels simultaneously, and combined with a high-speed return system, their output efficiency is usually 3 to 5 times that of traditional machines. Whether handling large-scale engineering orders or dealing with hundreds of different-sized orders daily, the automated positioning system can achieve seamless switching, eliminating downtime caused by manual adjustments.

Reduced Reliance on Manual Labor, Alleviating Labor Shortages

Skilled panel cutting operators are not only highly paid but also difficult to recruit and retain. Automated Panel Saws significantly lower the operating threshold. Operators do not need years of woodworking experience; they can be trained to monitor machine operation after simple training. Standardized operating procedures minimize the impact of personnel turnover on production quality, greatly enhancing the replicability of factory operations.

Analysis of the Core Advantages of Automated Panel Saws

Automatic Loading and Unloading and Intelligent Layout Optimization

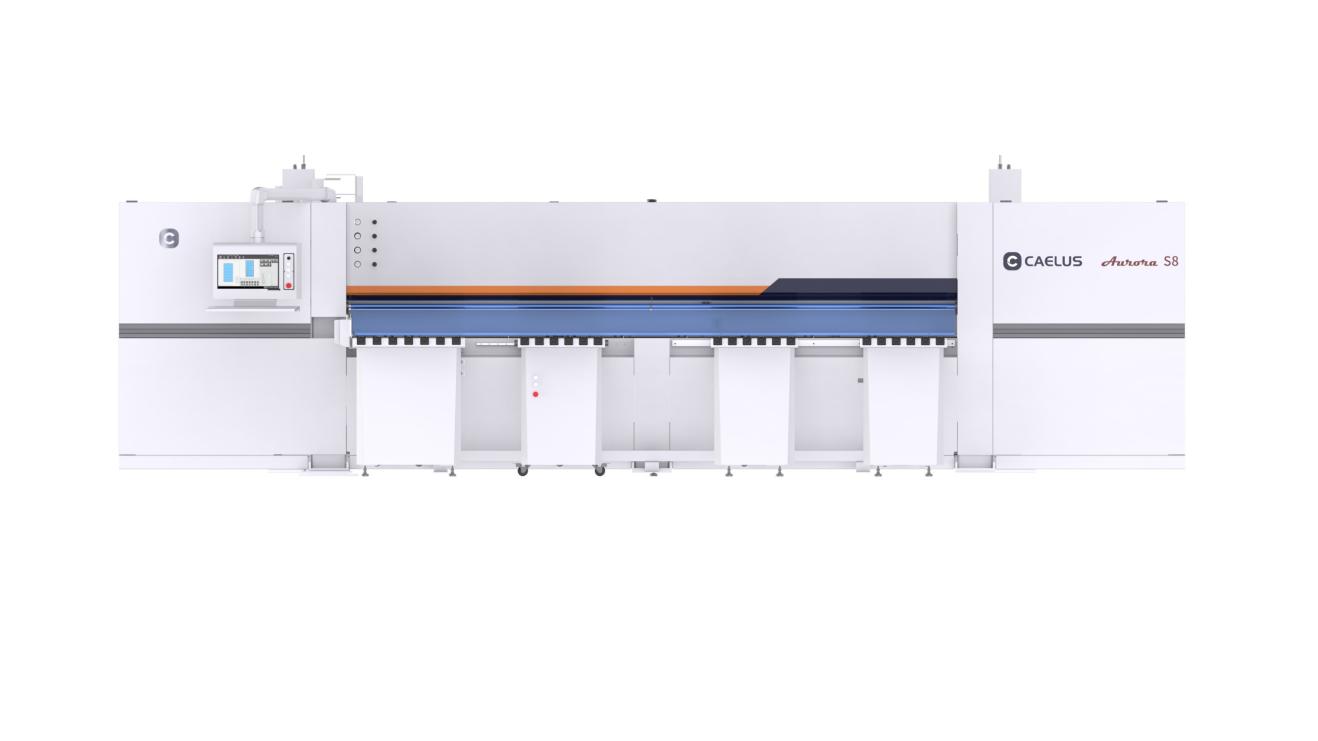

Modern automated Panel Saws often no longer operate independently, but are connected to automatic loading platforms or intelligent warehousing systems. For example, Caelus's Aurora S8 rear-loading model supports automatic feeding and positioning of large quantities of panels, completely freeing workers from manual labor. In material handling, automation reduces the risk of panel damage caused by manual handling and significantly improves the overall production cycle.

Software-Driven Cutting Optimization

Hardware determines the lower limit of cutting, while software determines the upper limit. The built-in optimization software can instantly calculate the optimal layout plan based on order requirements, maximizing panel utilization. The system automatically prioritizes remnant management, marking and storing large remnants in a database for future use, a cost advantage that manual layout cannot match.

Long-Term Value of CNC Panel Saws for Furniture Manufacturing

Upgrading machinery is not just a one-time capital investment, but an investment in the future of the brand. Stable delivery capabilities are key to winning the trust of large B2B customers. When your factory can promise extremely low error rates and on-time delivery, your brand image will naturally improve.

More importantly, CNC Panel Saws are the gateway to Manufacturing Automation. They are the foundation for building a smart factory ecosystem, enabling data exchange with edge banding machines, six-sided drilling machines, and MES systems, laying a solid data foundation for achieving a fully automated "dark factory" in the future.

Applications of CNC Panel Saws in Different Furniture Production Models

Factories of different sizes and positions have different machine needs. Caelus provides a full range of solutions from entry-level to top-of-the-line:

1. Small and Medium-Sized Factories and Standardized Production Lines: Pilot Series

For factories undergoing transformation, the Pilot S3 and Pilot S5 are ideal entry points.

The Pilot S3, as an entry-level benchmark, is equipped with an intelligent sawing control system and high-density clamps, achieving a leap from manual to CNC control with extremely high cost-effectiveness. The Pilot S5 further upgrades the servo-driven lifting main saw and linear-driven saw carriage, and the addition of an independent dual-push system makes it even more versatile when handling mixed orders.

2. High-End Customization and Large-Scale Manufacturing: Aurora Series

Facing massive orders and extreme precision requirements, the Aurora series demonstrates industrial-grade capabilities.

The Aurora S6 introduces linear motor drive technology and laser deformation detection, combined with an intelligent labeling system, perfectly suited for highly automated production lines.

The Aurora S8 is designed for high productivity, with a rear-mounted structure supporting double-layer stacking assistance, making it the flagship choice for those seeking ultimate cost-effectiveness and output.

3. Pioneer of Intelligent Manufacturing: Bespoke Flexible Unit

For companies aiming to create an Industry 4.0 benchmark, the SawTekRob 5 Flexible Cutting Cell is no longer just a simple saw, but a flexible cutting center integrating robotic automatic handling, flipping, and multi-process integration, representing the future of panel processing.

Table 1: Selection Guide for Caelus Panel Saw Series

|

eries |

Ideal Production Mode |

Key Technology |

Automation Level |

|

Pilot S3/S5 |

SME / Batch Processing |

Servo Control, Intelligent Clamps |

Standard |

|

Aurora S6/S8 |

Mass Customization / High Volume |

Linear Motor, Laser Detection, Auto Labeling |

High |

|

SawTekRob 5 |

Unmanned / Smart Factory |

Robotics Integration, Flexible Cell |

Fully Automated |

Key Factors to Consider When Upgrading CNC Panel Saws

When selecting a machine, factory owners should consider the following dimensions:

Cutting Size and Production Capacity Matching: Manufacturers should confirm the maximum panel size (such as the common 4x8 feet or large panels) and daily cutting volume to avoid "underpowering" or overcapacity.

Relationship between Automation Level and Factory Scale: The higher the degree of machine automation, the higher the requirements for the surrounding logistics system. Automated Panel Saws require corresponding dust removal, air supply, and panel handling space.

Connectivity with Downstream Panel Processing Machines: Excellent CNC Panel Saws should have open data interfaces to seamlessly transmit cutting information (such as QR codes) to subsequent edge banding machines and CNC drills, enabling a smooth information flow.

Contact Caelus to get the most suitable furniture production solution for your factory, production, and specific needs.

Table 2: Traditional vs. CNC Panel Saw Operational Comparison

|

Feature |

Traditional Panel Saw |

CNC Panel Saws (e.g., Caelus Aurora) |

|

Cutting Accuracy |

0.5mm - 1.0mm (Operator Dependent) |

0.1mm (Consistent) |

|

Optimization |

Manual Calculation |

Software Driven (High Yield) |

|

Labor Requirement |

Skilled Carpenters Required |

General Operator (Low Skill Barrier) |

|

Data Integration |

None |

Full MES/ERP Connectivity |

|

Safety |

High Risk of Injury |

Fully Enclosed, Sensor Protected |

FAQ

Q1:What are CNC Panel Saws?

They are automated cutting machines that control the movement of the saw blade and the positioning of the panel through a computer numerical control system, significantly improving cutting accuracy and efficiency.

Q2:What are the advantages of CNC Panel Saws compared to traditional Panel Saws?

Key advantages include micron-level cutting precision, production speeds several times faster than manual methods, higher material utilization, and reduced reliance on operator skills.

Q3:Are automated Panel Saws suitable for small and medium-sized furniture factories?

Absolutely. Entry-level models like the Pilot series can help small and medium-sized factories reduce waste costs and improve product quality, quickly recouping their investment.

Q4:What are the uses of Panel Saws in furniture manufacturing?

They are mainly used for cutting base materials such as particleboard, MDF, and plywood, and are widely used in the production of cabinets, wardrobes, office furniture, and door panels.

Q5:Do CNC Panel Saws help reduce production costs?

Yes. Although the initial investment is higher, the long-term operating costs are significantly lower than traditional machines due to reduced waste, lower labor costs, and elimination of rework.

Conclusion: Why CNC Panel Saws are the inevitable choice for modern furniture manufacturing

From the precise entry-level Pilot series to the high-efficiency output of the Aurora series, and the robotic collaboration of SawTekRob, Caelus offers more than just machines; it provides future-oriented productivity tools.

In the field of furniture manufacturing, upgrading to CNC Panel Saws signifies a shift from a manual workshop mindset to a modern industrial mindset. It solves the most fundamental and critical cutting problems in panel processing, paving the way for subsequent high-quality production. For manufacturers who aspire to be invincible in the market, embracing automated Panel Saws is the only way to a future of efficiency, intelligence, and high profits.