FAQ

Q1: What is automated Furniture Manufacturing?

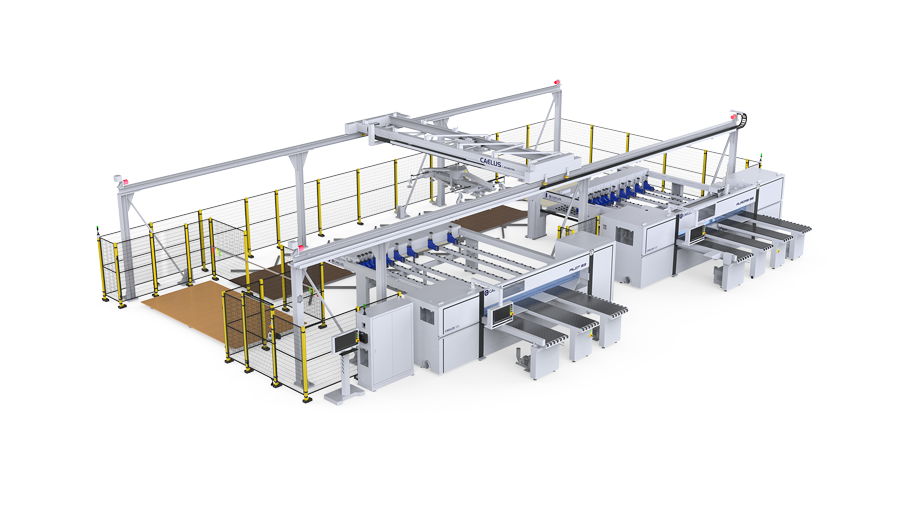

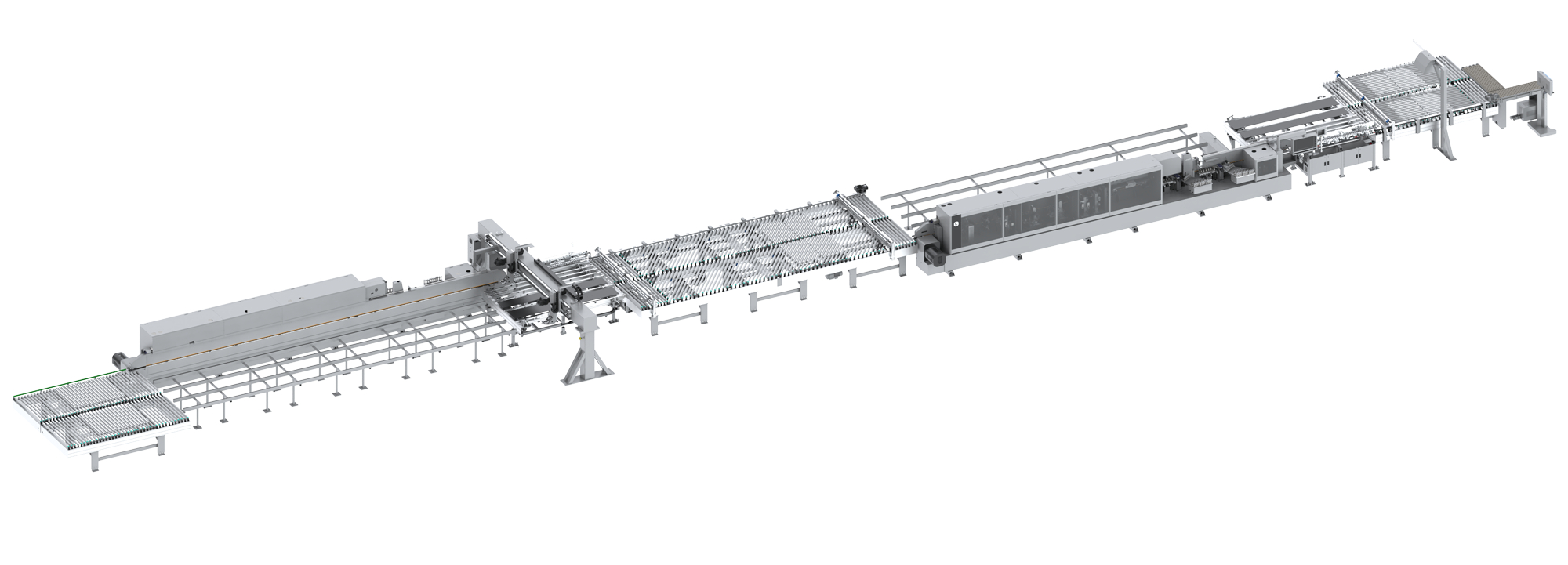

A: Automated Furniture Manufacturing uses intelligent integrated line solutions to automatically connect all furniture production stages, including raw material input, panel storage, cutting, processing, edge banding, and inspection, achieving a highly efficient production process with minimal or no human intervention. This is a core path for modern furniture manufacturing companies to improve capacity and quality.

Q2: What machines are included in Caelus's automated Furniture Manufacturing solution?

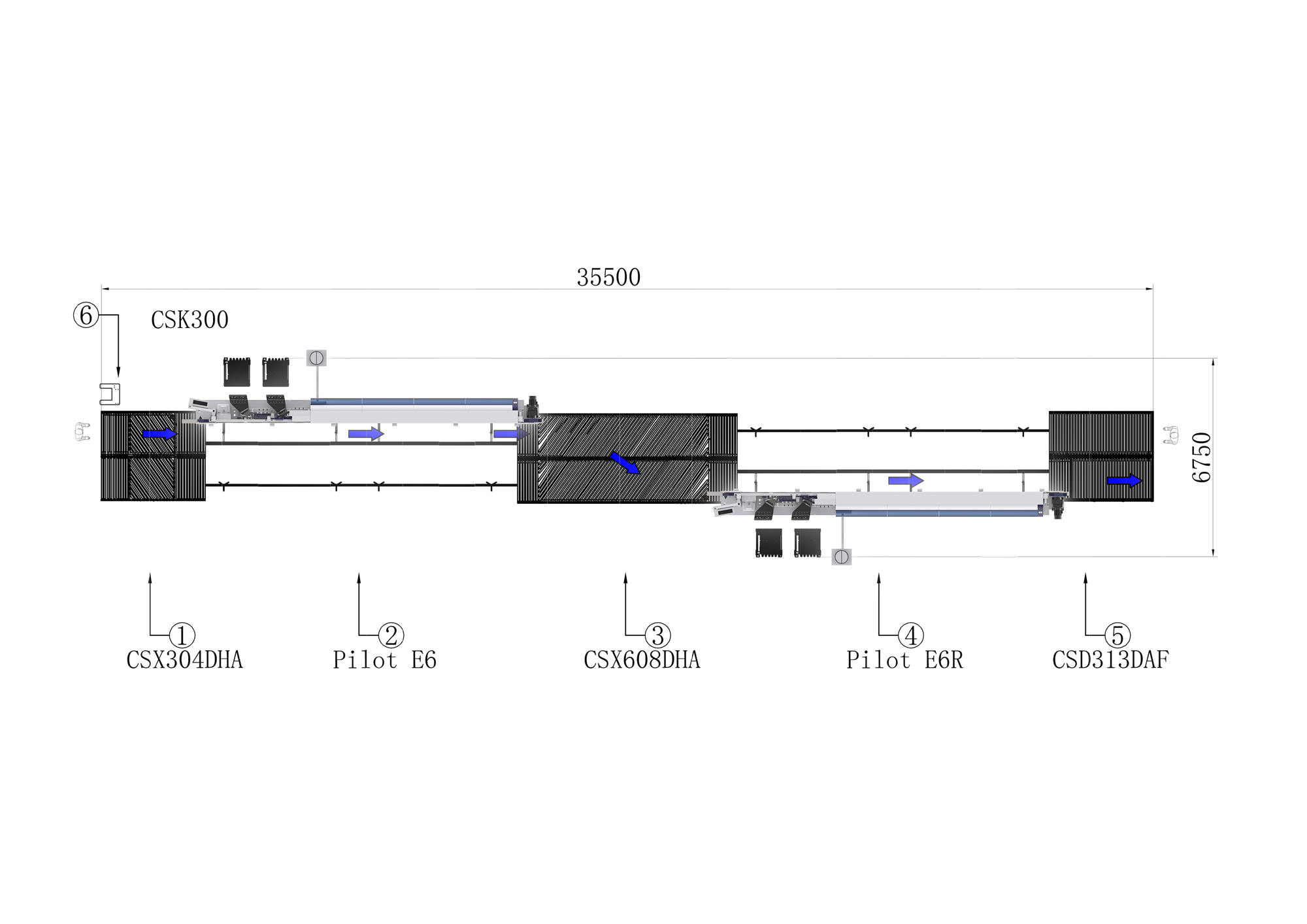

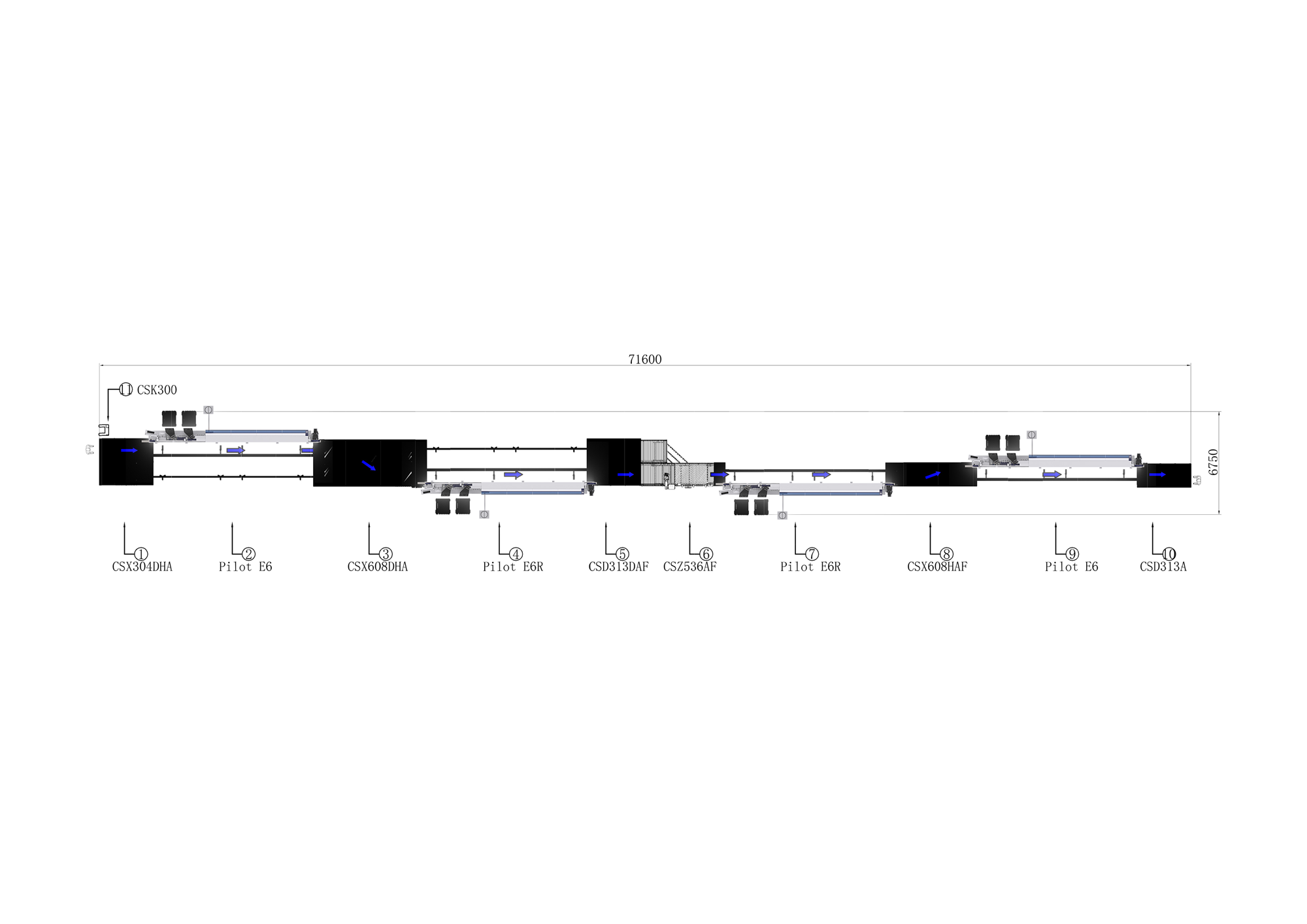

A: The solution covers a complete panel processing chain, mainly including:

These machines can be combined according to production line requirements to achieve full-process automation from loading to finished product.

Q3: What is high-precision panel processing? Why is it important?

A: High-precision panel processing refers to the use of advanced machines and control systems to achieve high-precision cutting, drilling, edge banding, and other processing techniques for furniture panels. High-precision processing reduces errors, improves product consistency, and reduces rework and material waste, making it a quality benchmark for modern furniture manufacturing.

Q4: What are the differences between automated furniture manufacturing solutions and traditional production?

A: Traditional production relies heavily on manual labor or semi-automatic machines, which often leads to production line bottlenecks, low efficiency, and unstable quality; while automated furniture manufacturing solutions, through intelligent scheduling, automatic feeding, online control, and MES system management, can achieve refined production processes, traceable data, significantly increased capacity, and reduced reliance on manual labor.

Q5: What improvements can Caelus Automatic Panel Storage bring to the production line?

A: Automatic Panel Storage can automatically store, classify, and retrieve panels, shortening loading waiting times, reducing manual handling costs, and improving the overall utilization rate of machines, enabling Panel Saws and other panel processing machines to operate continuously and efficiently.

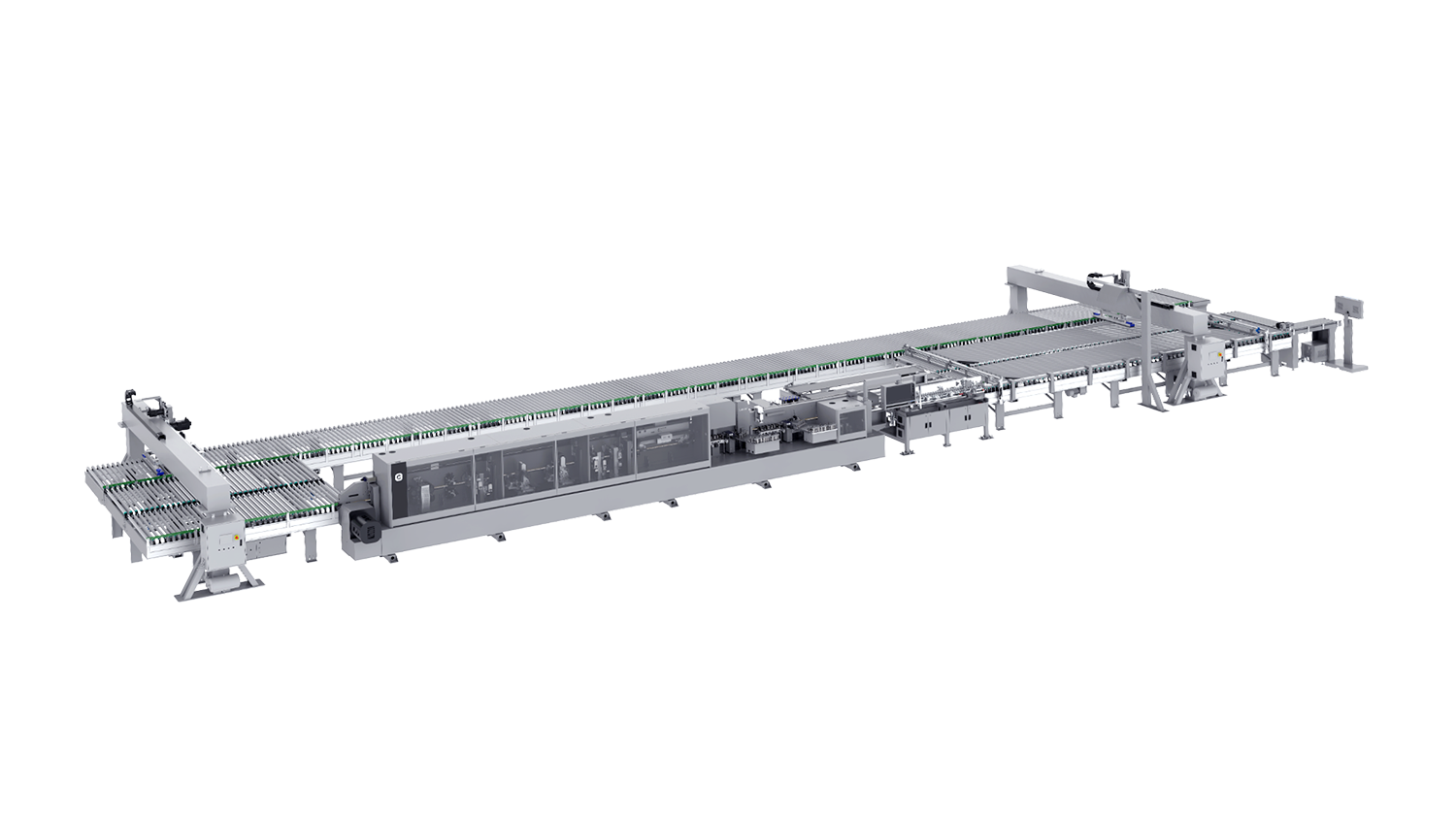

Q6: What role does the Edge Bander play in automated furniture manufacturing?

A: The Edge Bander is an important processing step after panel processing. It provides high-quality edge banding for the edges of cut panels, improving the aesthetics and durability of furniture. When integrated with an automated production line, it enables continuous, unmanned edge banding processing.

Q7: Do these machines support connection with MES/ERP systems?

A: Yes. Caelus's automated furniture manufacturing solution supports connection with MES/ERP systems, enabling order management, production scheduling, status monitoring, and data tracking, thus creating a truly smart factory.