凯澳智能:覆盖板式家具全流程的智能装备解决方案

凯澳智能提供覆盖板式家具全生产流程的智能装备,核心机型包含电子锯、自动板材仓储系统、封边机等。依托高性能数控装备与自动化控制技术,凯澳智能为家具生产企业打造高效、高精、柔性的板材加工方案,兼容多品类产品生产,助力企业迈向智能化、数字化制造新阶段。

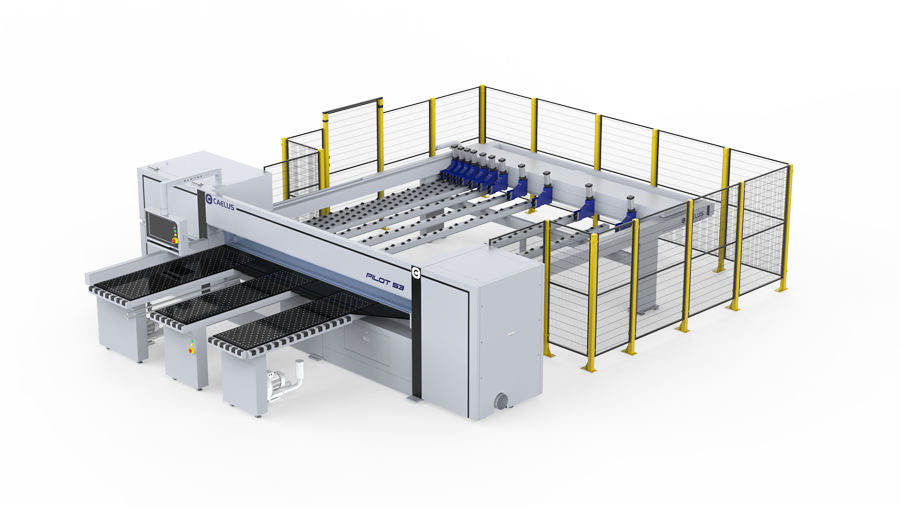

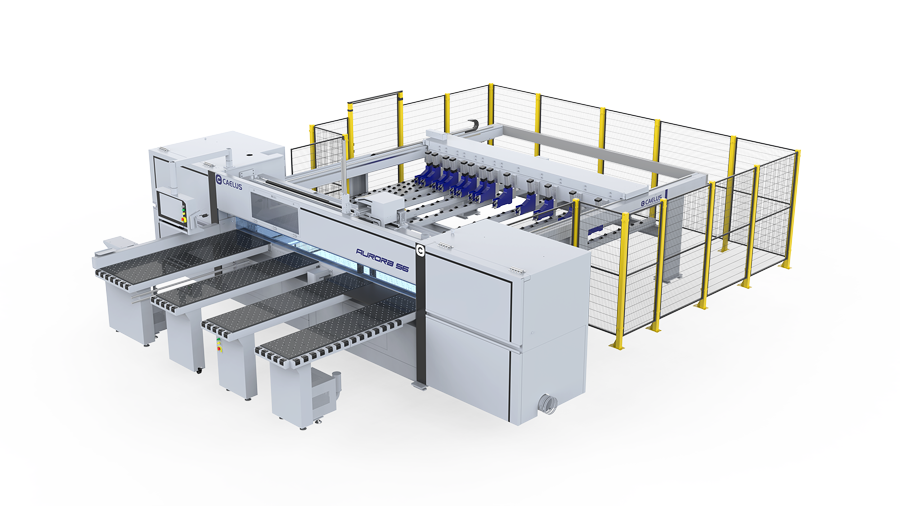

电子锯 —— 高精板材切割核心设备

凯澳智能电子锯专为板式家具制造的精密切割需求设计,可满足多规格、多批次板材的裁切加工。设备采用重型高精机架结构,搭载伺服与直线驱动技术及智能控制系统,实现高速切割状态下的超高稳定性与重复定位精度。

凯澳智能电子锯核心优势

- 重型稳定结构,保障长期加工精度

- 伺服高响应驱动系统,实现高速精准切割

- 智能优化排版功能,提升板材利用率

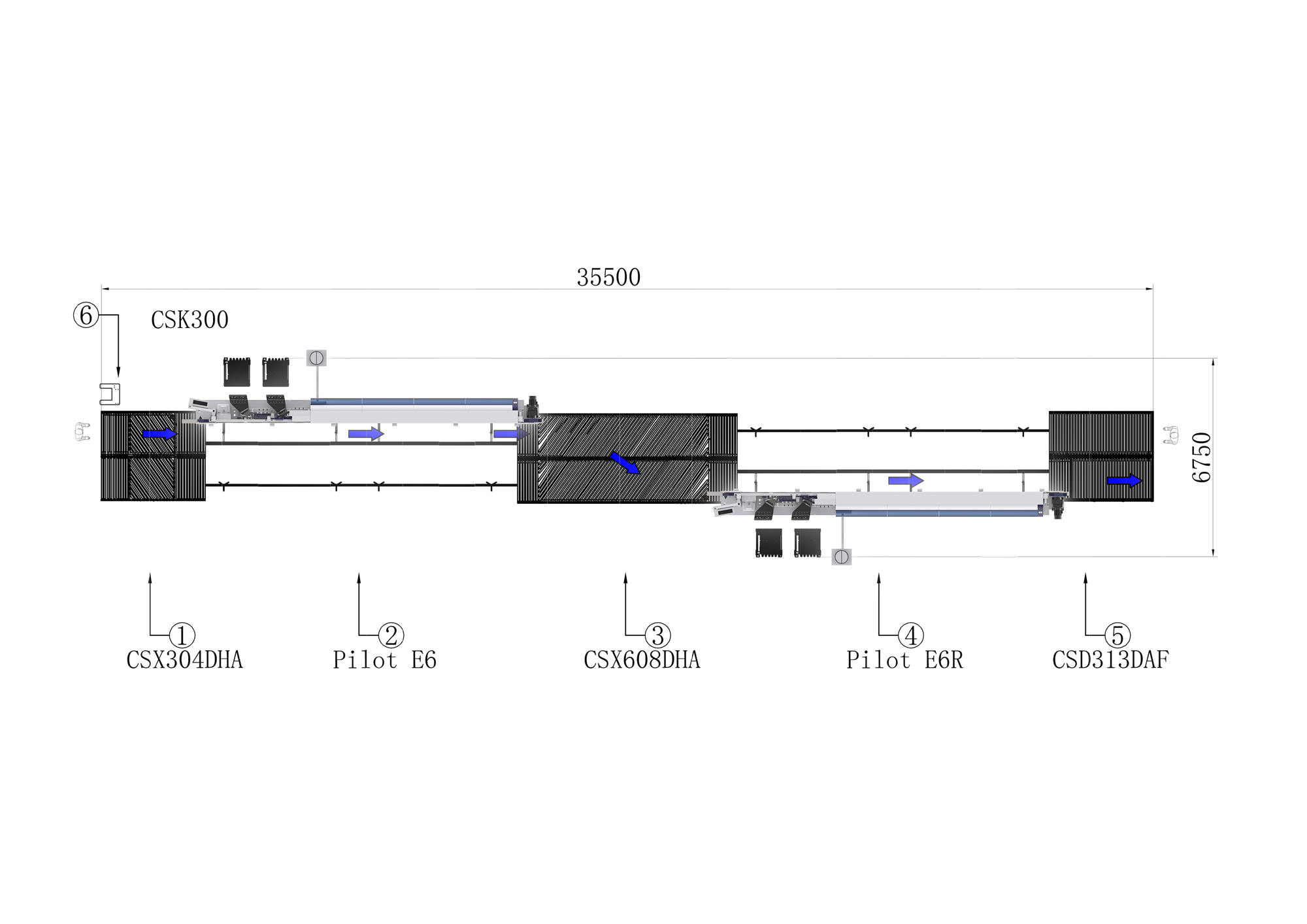

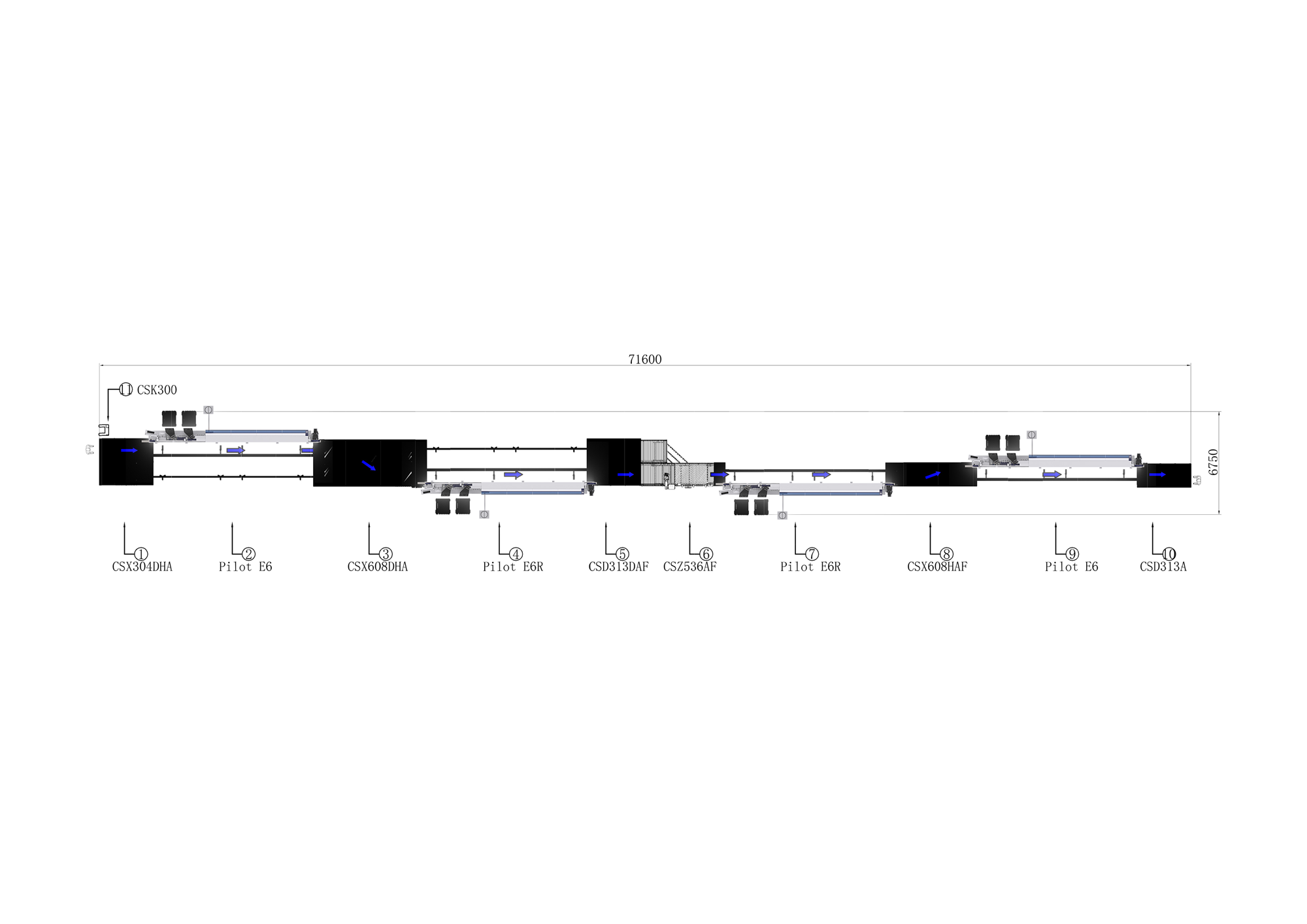

- 可对接自动板材仓储系统及数控设备,搭建自动化板材切割生产线

- 适配范围广,覆盖入门级精密切割至全自动化工厂柔性加工需求

适用场景:大型家具生产企业、定制化柔性生产线、多品类板材加工企业

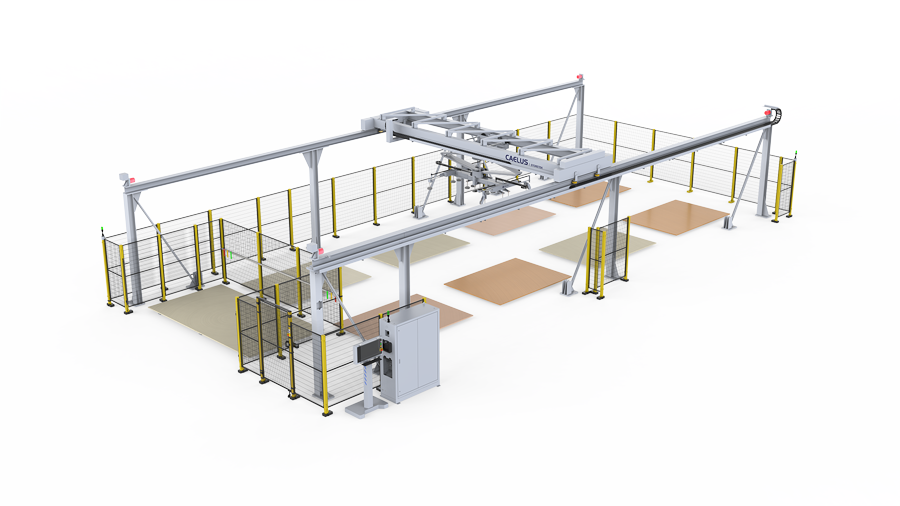

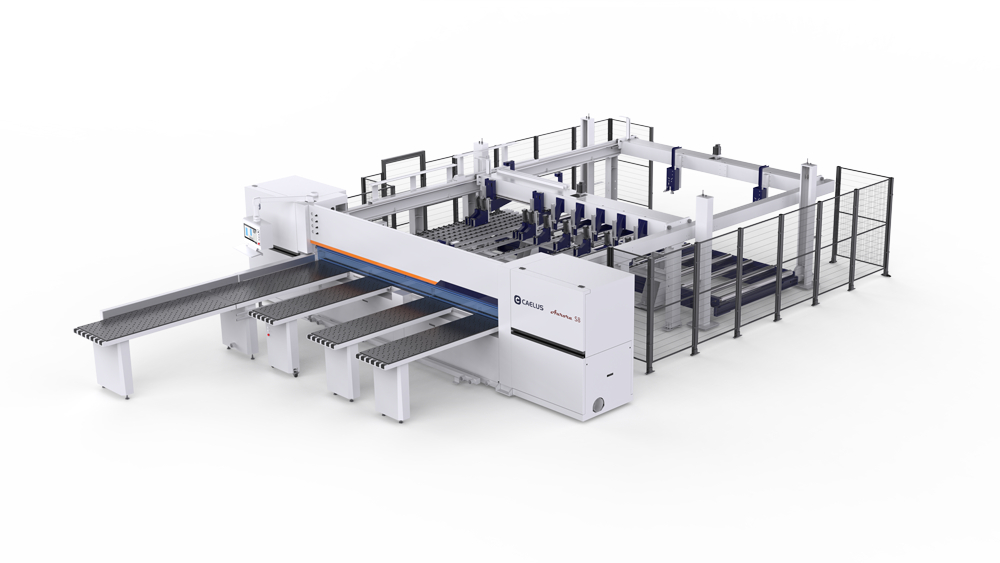

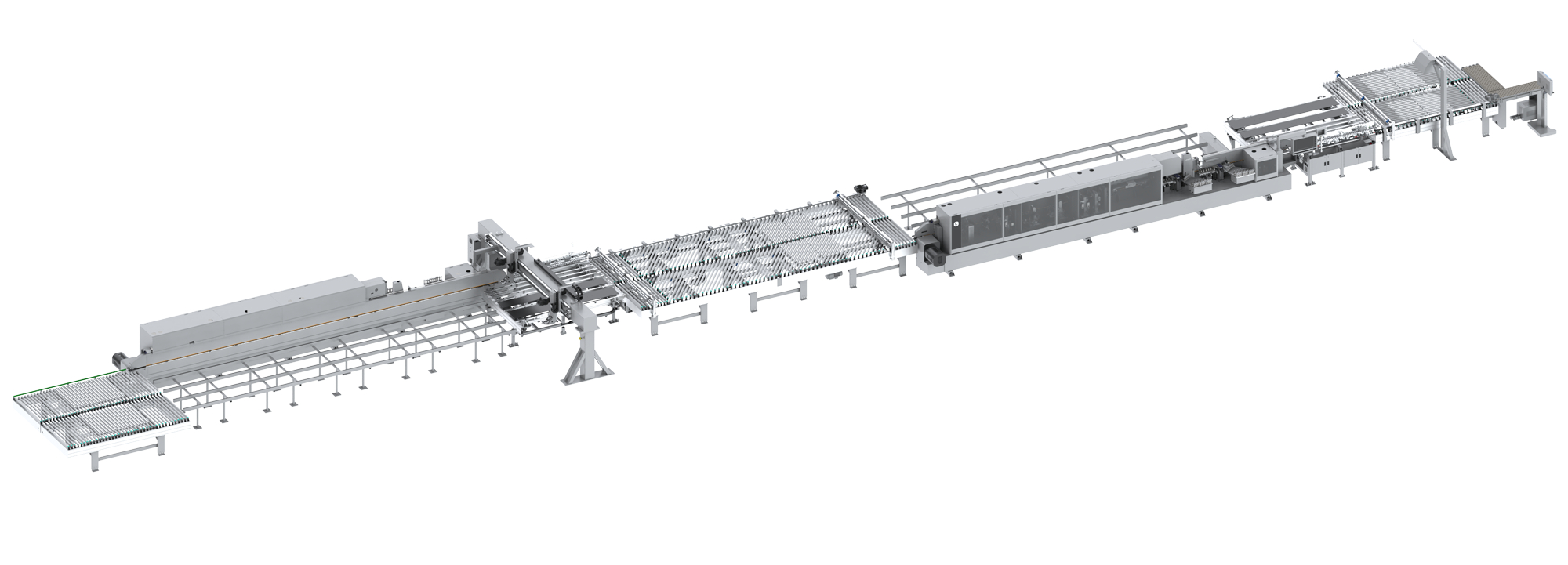

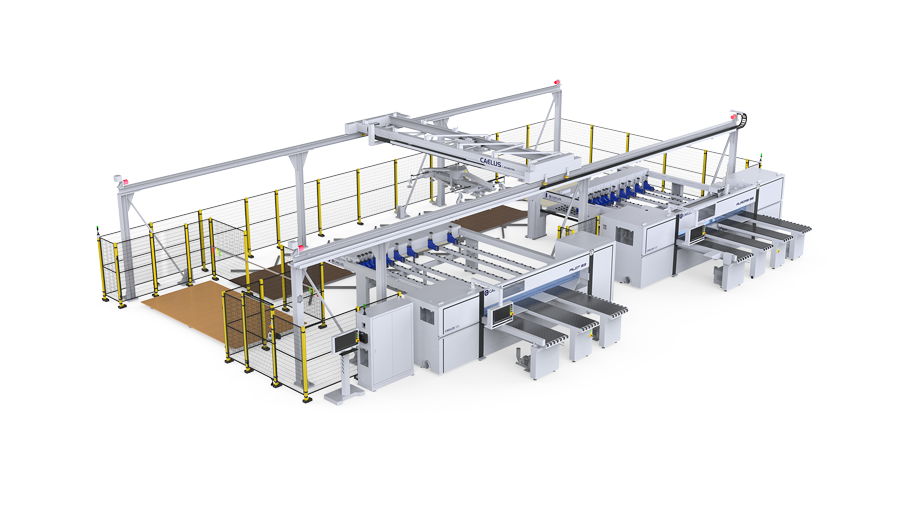

自动板材仓储系统 —— 智能板材物流调度平台

凯澳智能自动板材仓储系统不仅是仓储设备,更是一套智能板材物流调度平台。系统可自动完成板材分拣、存储、识别、路径优化及输送全流程,保障生产线持续高效运转。

凯澳智能自动化立体仓储系统(AS/RS)核心价值

- 大幅降低人工搬运成本

- 保障电子锯及下游产线不间断供料,产能提升 10%-30%

- 自动识别、调取、分拣物料,减少混料、错取、板材损伤等人为失误

- 提高板材利用率,优化生产节拍

- 无缝对接电子锯、封边机全系列设备,实现智能工厂闭环管理

适用场景:致力于提升工厂效率、降低人工依赖、打造数字化仓储管理体系的制造企业

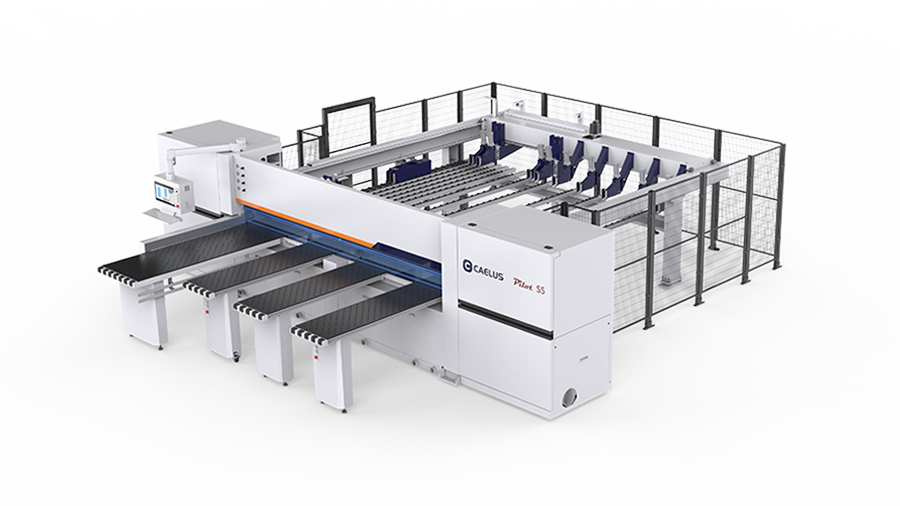

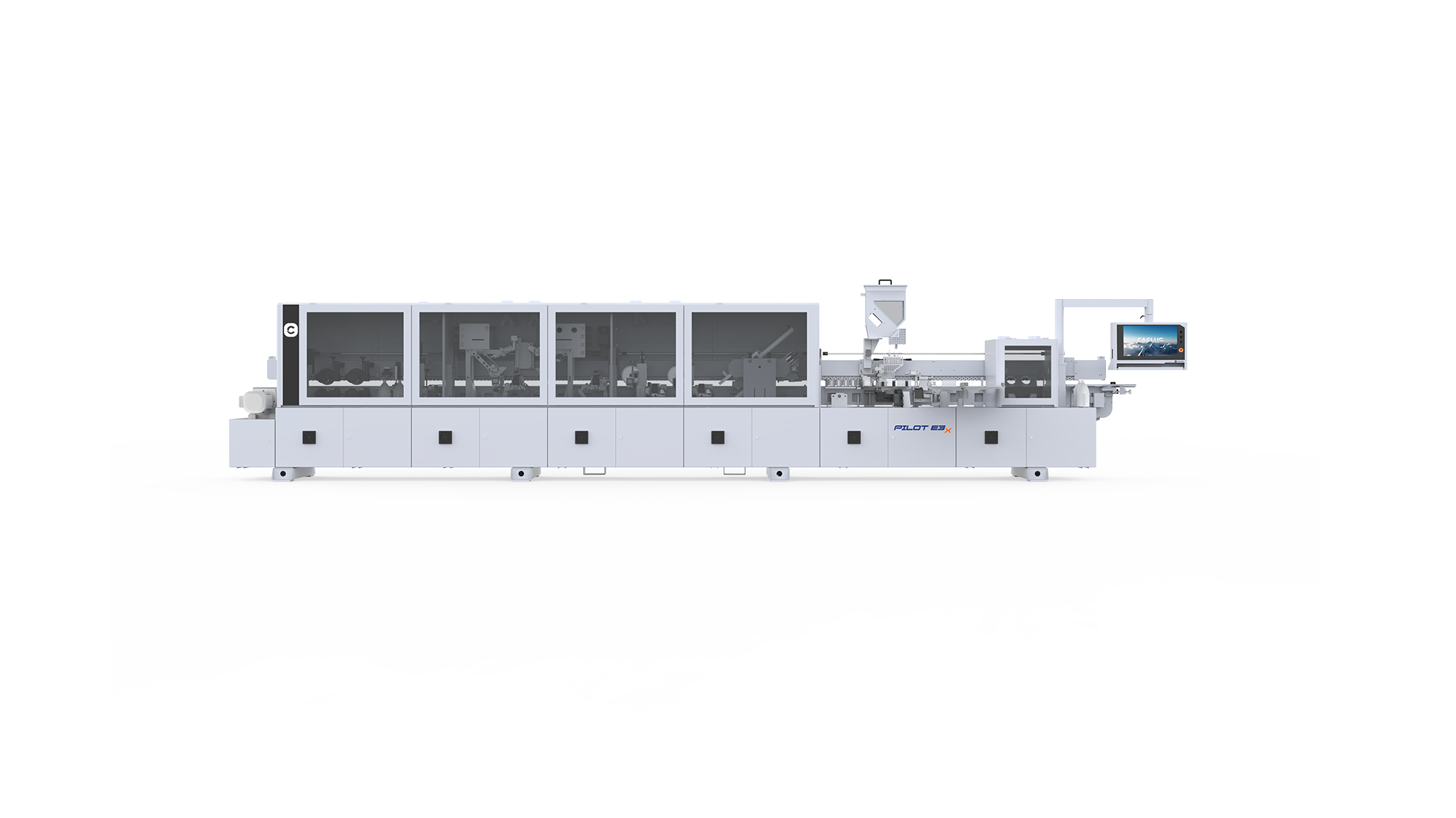

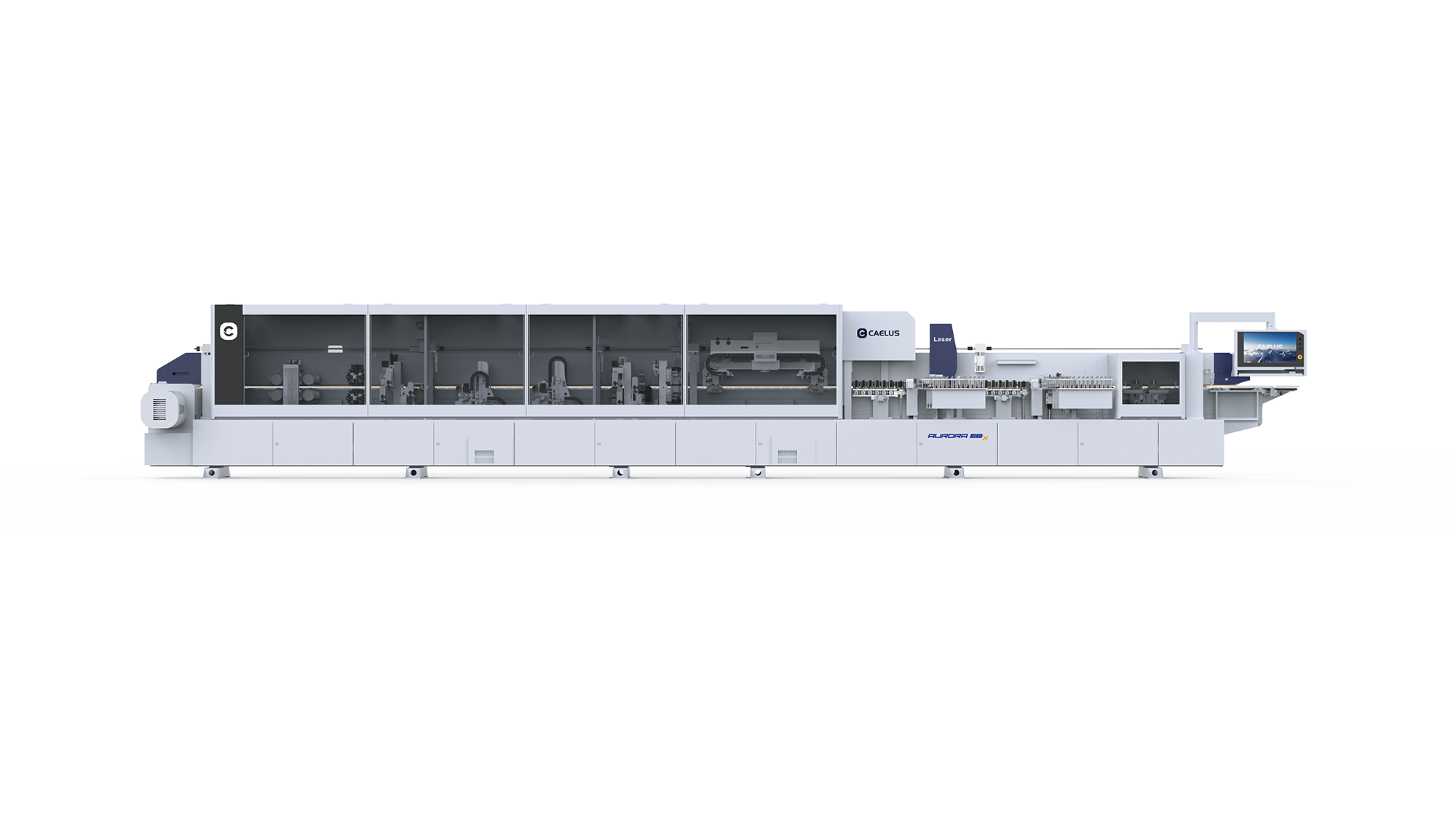

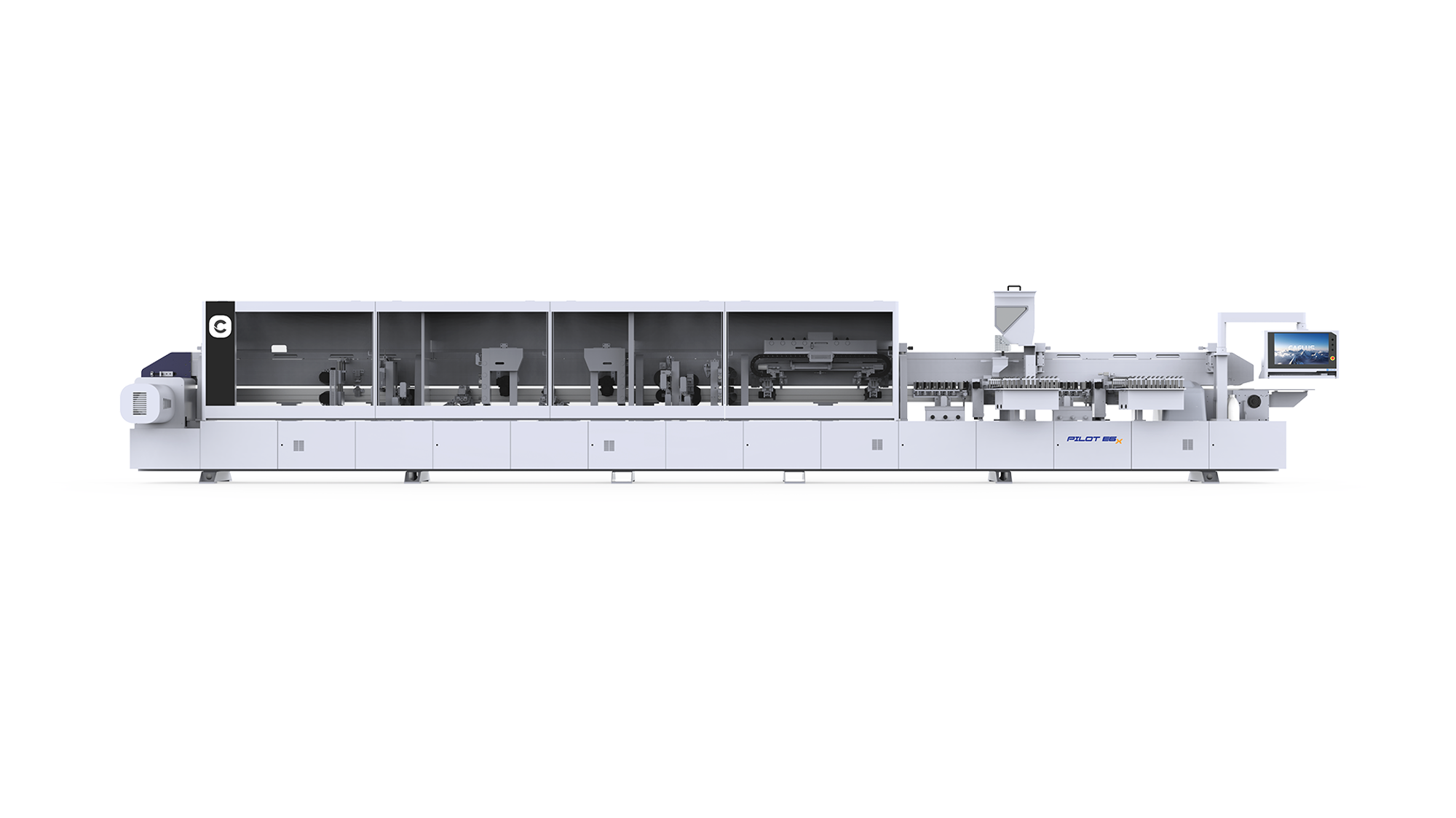

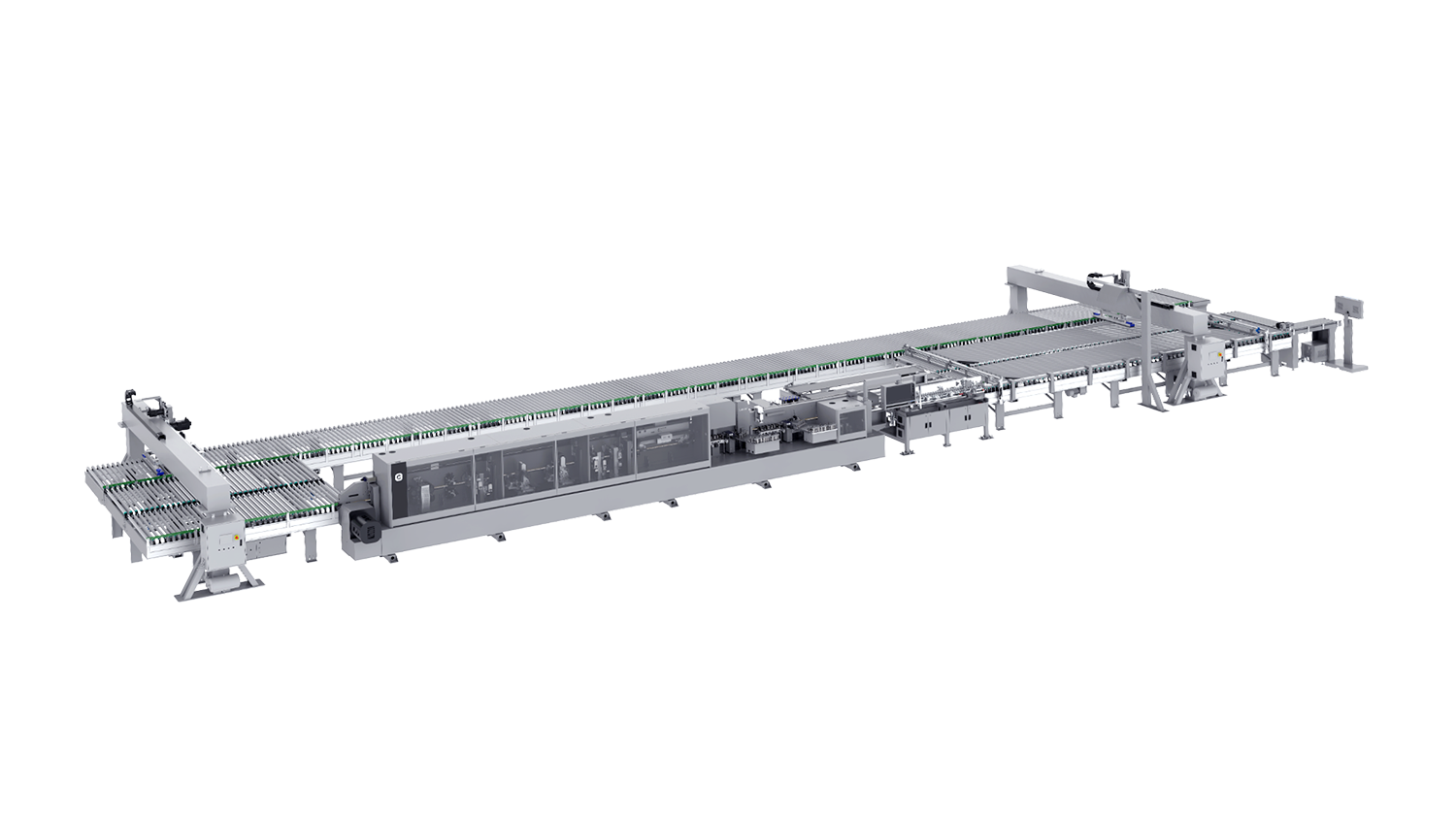

封边机 —— 高品质家具成型关键工序设备

凯澳智能封边机采用重型机架结构,具备柔性换单、伺服高精控制、智能维护三大核心优势,可适配各类封边材料与复杂工艺,确保封边效果光滑牢固、美观一致。

凯澳智能封边机核心优势

重型机架结构,运行更稳定;伺服系统精准控制,保证涂胶贴合牢固、修边精度优异;加工速度快,兼容各类封边工艺与材料;换单柔性强,适配定制化、小批量、混线生产模式;智能维护系统搭配高可靠性电控架构,降低停机时间与维护成本;可对接电子锯等数控设备,组成完整封边加工中心。

适用场景:追求高品质封边效果与高效率生产的家具制造企业